In many countries one of the biggest sources of fine particles is domestic wood combustion. Especially during the winter months abr. 40% of all fine particle emission is generally caused by domestic wood combustion.

Emissions are a real and serious risk for our health and with abatement technologies you can help the situation! The fact is that bio fuel combustion emission is a major reason for fatal deceases. Emission limits have been reduced during the past years and the pressure for even lower pollution levels increases in the coming years.

What you can do to reduce the combustion emissions at home? Improved combustion technology together with auxiliary filter devises is the solution now and in the future.

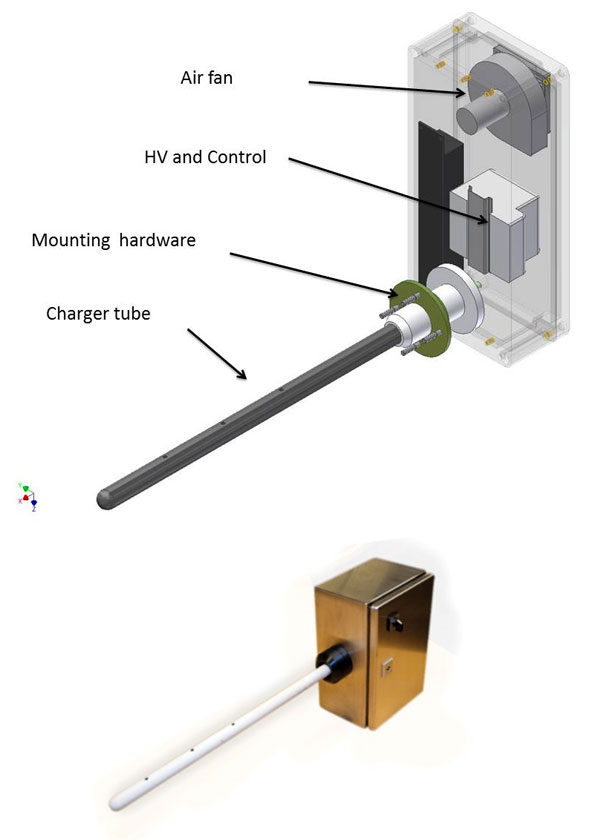

Tassu EDF is a novel technology based on electric diffusion charging, which solves the problem. EDF charger is installed in your combustion devise and plugged in the electric source-“plug and play”. Dust is collected in the ash box and is then removed during normal cleaning/maintenance routines.